Every year, before the first freeze, the ritual of irrigation "blow out" becomes the priority for all irrigation systems in regions located where the frost level extends below the depth of installed piping.

Due to the potential dangers involved with winterization, it is best to call a professional.

Click here to locate an irrigation professional near you.

Even if you have drained the water out of your irrigation system, some water remains and can freeze, expand, and crack PVC piping (rigid, white pipe). Polyethylene pipe (flexible, black pipe) is used in many freezing climates. Although polyethylene pipe is more flexible and can expand under pressure, water left inside can freeze and rupture the pipe walls. Freezing water in the backflow assembly will damage the internal components and can crack the brass body.

To minimize the risk of freeze damage, you'll need to winterize your irrigation system. In areas where winterization is mandatory, irrigation systems are installed using one of two types of water removal: manual drain or blowout. If you don't know your system type, it is best to use the blowout method.

Blow Out Method |

|---|

WARNING! Wear ANSI-approved safety eye protection! Extreme care must always be taken when blowing out an irrigation system with compressed air. Compressed air can cause serious injury, including serious eye injury, from flying debris. Always wear ANSI-approved safety eye protection and do not stand over any irrigation components (pipes, sprinklers, and valves) during air blowout. Serious personal injury may result if you do not proceed as recommended! It is best for a qualified licensed contractor to perform this type of winterization method.

The blow-out method utilizes an air compressor with a specific Cubic Foot per Minute (CFM) rating. A common formula is to use the total GPM of the largest zone divided by 7.5 for the required CFM at the point of connection to the irrigation system. Pressure should not exceed 50 psi for polyethylene pipe or 80 psi for PVC pipe. These types of compressors can be rented at your local equipment rental yard. Do not attempt to fully charge the holding tank and then release the highly pressurized air flow into the mainline to compensate for the compressor's lack of CFM. The compressor is attached to the mainline via a quick coupler, hose bib, or other type of connection, which is located after the backflow device. Compressed air should not be blown through any backflow device.

- To start the blowout, shut off the irrigation water supply.

- Attach the air compressor hose to the fitting with the compressor valve in the closed position.

- Activate the station on the controller, which is the zone or sprinkler's highest in elevation and the furthest from the compressor.

- Close the backflow isolation valves.

- Slowly open the compressor's valve; this should gradually introduce air into the irrigation system.

- The blowout pressure should remain below the maximum operating pressure specification of the lowest pressure-rated component in that zone.

Each station/zone should be activated starting from the furthest station/zone from the compressor, slowly working your way to the closest station/zone to the compressor. Each station/zone should be activated until no water can be seen exiting the heads; this should take approximately two minutes or more per station/zone. Using two or three short cycles per station/zone is better than having one long cycle. Once the station/zone is dry, you should not continue to blow air through the pipe. Compressed air moving through dry pipes can cause friction, which will create heat and could cause damage. Never run the compressor without at least one irrigation control valve open.

Once the water has been removed from the irrigation system, disconnect the air compressor and release any air pressure that may be present. If your backflow device (the most common backflow installed is called a Pressure Vacuum Breaker) has ball valves, open and close the isolation valves on the backflow device numerous times to ensure that any trapped water has escaped from the upper areas. Leave the isolation valves open at a 45° angle (approximately 1/2 open) and open the test cocks.

IMPORTANT TIPS:

- Do not leave flow sensors installed. Always remove them first and seal the pipe to avoid damage to the sensor.

- Do not stand over component parts while the system is pressurized with air.

- Do not leave the air compressor unattended.

- Do not blow the system out through a backflow or pump. First, blow out the system, then drain the backflow or pump.

- Do not leave the manual drain valves (if installed) open after the blowout.

- Follow the manufacturer's recommendations to winterize any irrigation system component.

Manual Drain Method |

|---|

Attempting the manual drain method in systems that were not initially designed/installed this way may lead to negative results and/or damage from residual water. Only use this method if you can confirm manual valves are located at the end and low points of the irrigation piping.

To drain these systems, simply shut off the irrigation water supply and open all the manual drain valves. Once the water has drained out of the mainline, open the boiler drain valve or the drain cap on the stop and waste valve (whichever is used in your area) and drain all the remaining water that is between the irrigation water shut off valve and the backflow device. Open the test cocks on the backflow device. If your sprinklers have check valves, you'll need to pull up on the sprinklers to allow the water to drain out of the bottom of the sprinkler body. Depending on the location of the drain valves, there could be some water left in the backflow, the piping, and the sprinklers. When all the water has drained out, close all the manual drain valves.

Preparing the System Components |

|---|

| Product | Tips |

|---|---|

| Outdoor Dial Controllers | Leave the power on and the dial / switch in the "OFF" position. The heat from the transformer will keep the enclosure warm enough to keep condensation from forming inside the controller enclosure. The dial in the "OFF" position will keep the controller from activating the solenoids in the field. |

| Indoor Dial Controllers | Leave the power on and the dial / switch in the "OFF" position. This will prevent the controller from activating the solenoids in the field. |

| Hydrawise Controllers | Hydrawise system allows you to suspend or temporarily disable watering for specific zones. Suspending a zone or zone(s) can be helpful in various situations, such as when you need to perform maintenance repairs or shut down your system for a season. Learn More |

| Rain Sensors | There is very little winter preparation required for rain sensors. If your sensor is the type with a cup or bowl that catches water, you might want to remove the water and place a plastic bag over the sensor. This will keep any water from accumulating and freezing in the cup or bowl area. |

| Flow Sensors | Flow sensors can potentially be damaged by winterization blowout techniques, so they should be removed prior to injecting compressed air into the pipes. |

Types of Valves |

|---|

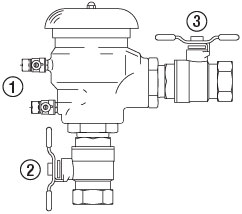

Pressure Vacuum Breaker

- PVB Test Cocks

- Isolation Ball Valve Inlet

- Isolation Ball Valve Outlet

Interior Point of Connection in Freezing Climates

- Boiler Valve

- Irrigation Shut Off Valve

- Main Water Shut Off Valve

- Water Meter

Gate Valve

Ball Valve

Stop and Waste Valve

Boiler Valve